CONTENTS

- Principle of the LoopiPak box

- Overall result of the environmental impact of the LoopiPak reusable box

- LCA considers the whole process, no step is ignored for a reliable conclusion

- An indisputable alternative to cardboard, the most common packaging for online order deliveries

- Principle of Life Cycle Assessment (LCA)

- Presentation of sensitivity analyses

- Technical details of assumptions

1. Principle of the LoopiPak reusable box

The Graine de Malice delivery box is used to pack and protect the contents of private individuals' online orders placed with a merchant who delivers via a carrier (at home or at a collection point). This box replaces any external cardboard packaging that is usually used.

This box is made of recuperated materials (advertising tarpaulins) or recycled materials (polypropylene) that are very resistant so that they can be reused a great number of times. After each use, it is cleaned before being reused. Its modular design allows for repairs during its lifetime, which further extends the number of possible uses.

Thanks to its reusability, the Graine de Malice box has a much lower impact on the environment than a single-use cardboard box.

LoopiPak from Graine de Malice

Pure product of the circular economy, designed and manufactured in Belgium, it is available in several sizes. It is the only truly zero-waste box that allows the return of returnable packaging to the retailer.

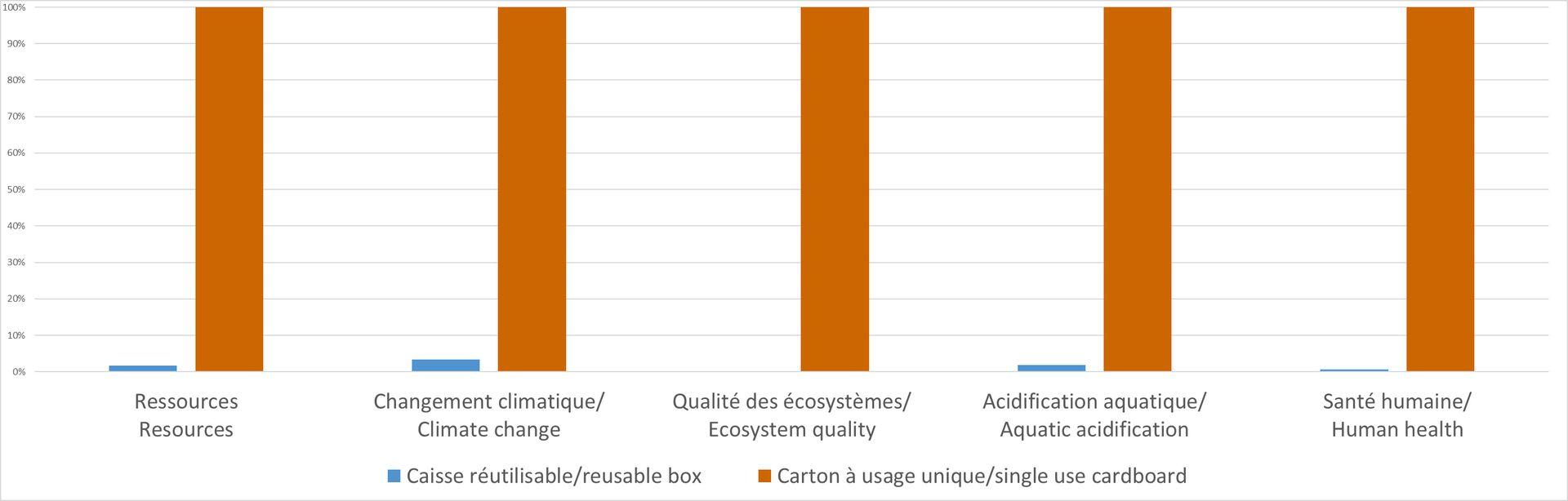

2. The overall result is clear: our reusable LoopiPak has a much better environmental impact than the cardboard box

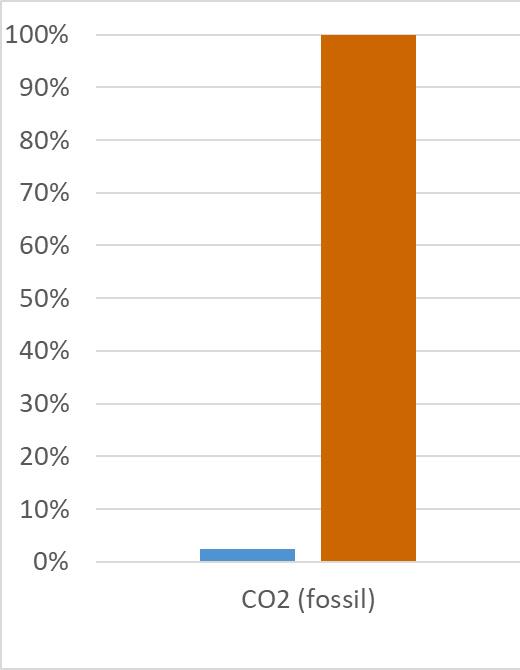

Using the reusable box produces on average more than 30 times less CO2 than using the single-use cardboard box. We are not talking about a 30% improvement but a 97% reduction!

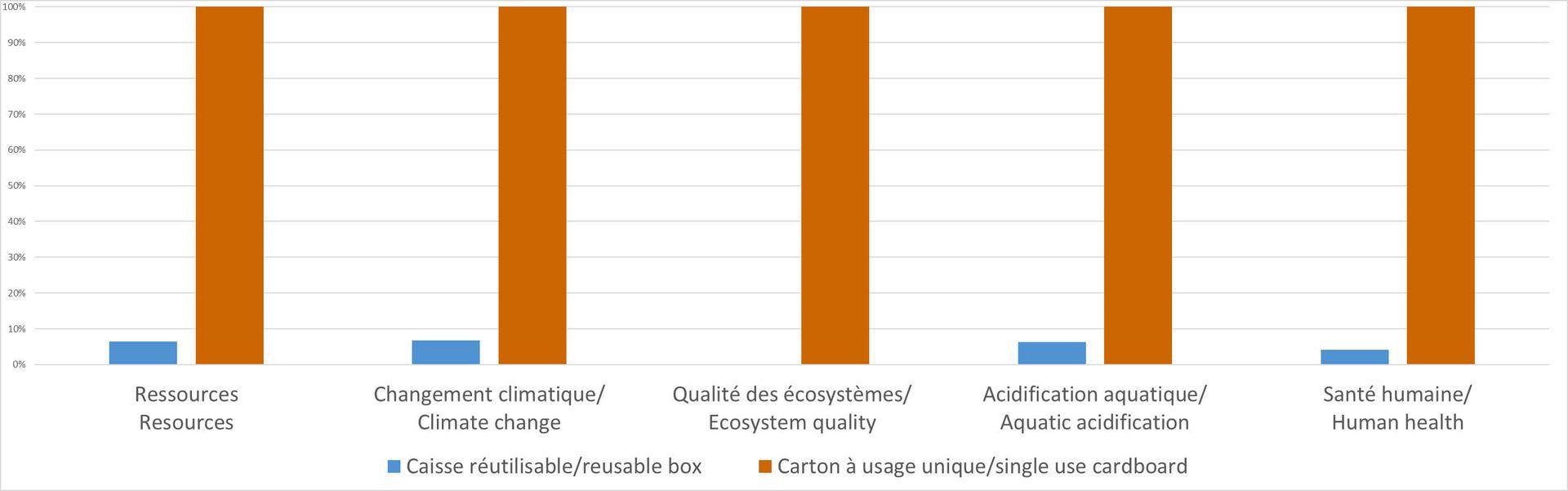

The impact on the environment is multidimensional, going beyond CO2 emissions. It takes into account methane emissions, nitrite in water, particles in the atmosphere. The improvement in these areas is even better.

3. LCA considers the whole process, no step is ignored to draw a reliable conclusion

In order to draw reliable conclusions, it is important to analyse a process that is as close as possible to the actual route that the box will follow. The process analysed is as follows:

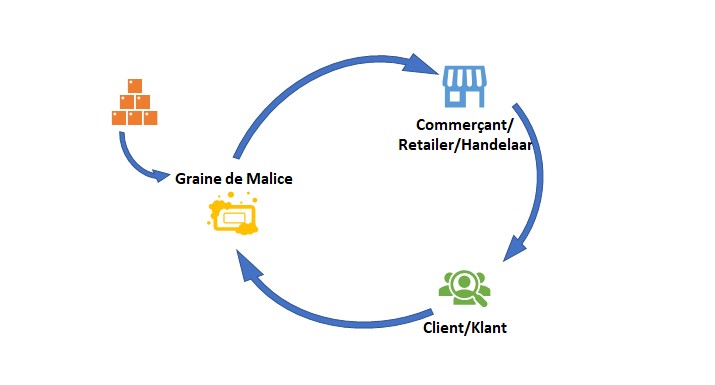

Scheme 1 : order without deposit or individual reusable packaging (e.g. a returnable bottle)

• Graine de Malice manufactures the box

• Graine de Malice provides the box office to the retailer

• The retailer packs the customer's order in the LoopiPak and hands it over to the carrier

• The LoopiPak is delivered to the customer

• The customer unpacks the order, folds the LoopiPak, flips over the shipping label and hands the folded box over to the carrier

• The box is dropped off by the carrier at Graine de Malice

• Graine de Malice cleans the LoopiPak, carries out a quality control and any repairs

The cycle starts again from point 2.

Route of the LoopiPak reusable box ( Scheme 1)

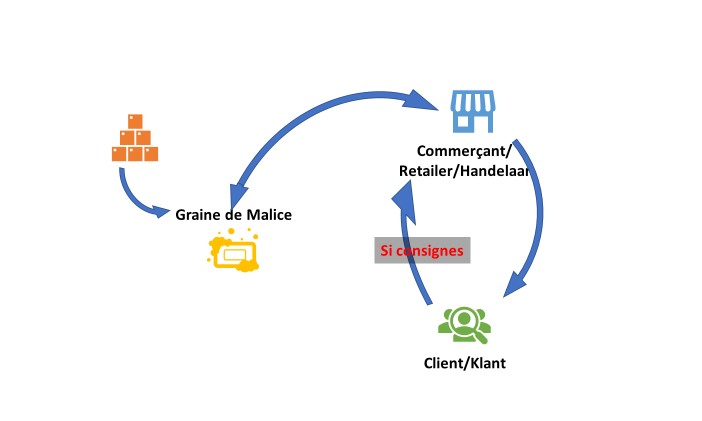

Scheme 2 : order with deposit or individual packaging to be returned to the retailer

• Graine de Malice manufactures the LoopiPak

• Graine de Malice provides the box office to the retailer

• The retailer packs the customer's order in the LoopiPak and gives it to the carrier

• The box is delivered to the customer

• The customer unpacks the order, folds the LoopiPak if necessary (depending on the volume of items to be returned to the retailer), flips the shipping label and hands the folded FlexBox to the carrier

• The box is delivered by the carrier to the merchant

• The retailer removes the deposits and returns from the box received, folds it

• The retailer hands over the empty LoopiPak to Graine de Malice, upon delivery of clean FlexBoxes by Graine de Malice

• Graine de Malice cleans the LoopiPak, performs a quality control and makes any necessary repairs

The cycle starts again from point 2.

Route of the LoopiPak reusable box with deposits and returns ( Scheme 2)

4. An indisputable alternative to cardboard, the most common packaging for online order deliveries

A single product LCA is difficult to use and inappropriate in our case. We are looking to greatly improve the impact of the cardboard packaging used in over 95% of online retail orders. We have therefore chosen to compare our box with its current equivalent: the single-use cardboard box of comparable dimensions.

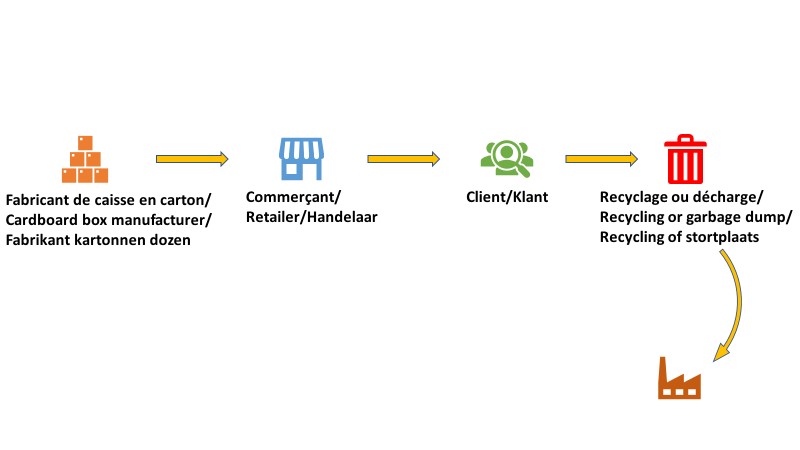

The process considered is the following:

• The producer makes the cardboard box

• The producer provides the box to the retailer

• The retailer packs the customer's order in the box and gives it to the carrier

• The cardboard box is delivered to the customer

• The customer unpacks the order, folds the box and gives it to the selective collection service for recycling

• Sometimes the box is reused first (statistics show an average reuse of 3%: 3 times out of 100)

• The folded box is collected and taken to the recycling/recovery centre

• The cardboard is recycled or valorised in a methanisation centre.

Route of the cardboard box

5. Principle of Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) is a quantitative scientific method for measuring the impact of a product on the environment. This analysis tries to be as complete as possible. It takes into account a whole range of elements such as the raw materials used, the use of the product and its disposal at the end of its life. This scientific and standardised approach, based on precise measurements, makes it possible to confirm choices and above all to avoid doing "worse than better" in good faith.

We have chosen the most complete scope of analysis, from the choice of raw materials to the disposal of the various components of the product at the end of its life, or the recycling of suitable materials.

An LCA is particularly useful as a comparison in an alternative. It easily allows the impact of a product to be assessed "in relation to" another very common product or use. This shows that an innovation is much more efficient - or not - than the usual use.

Finally, to be sure that a change in use is beneficial to the environment, the new solution must be several times better than the usual solution (e.g. 3 times better), over the whole range of variation in assumptions.

6. Presentation of sensitivity analyses

For a small cardboard box (e.g. 20x20x20cm), the CO2 generation is 25 times lower. For a medium sized box (40x40x40cm), it is 50 times less !!

Even if we were to use new tarpaulin, the improvement is already very significant: 15 times less CO2 emitted with each use.

Comparison with new tarpaulin, medium-sized box :

Reusing the cardboard box is obviously a reflex that one should already have. However, cardboard boxes deteriorate quickly. The current reuse rate is estimated at 3%. Increasing the reuse rate to 20% (which has never been done) would improve the performance of the cardboard box, but the reusable box is still far superior (25 times less CO2 instead of 30 times less).

7. Technical details of the assumptions

LCAs are sensitive to assumptions. Assumptions are necessary because actual usage data are unknown. Realistic average estimates are then made, such as for the distance to be travelled between the retailer and the customer, or between the Graine de Malice workshop and the retailer.

Specific assumptions of the scenarios

- each box is steam cleaned after each use

- the reusable box is used at least 50 times (tests show a much higher capacity)

- polypropylene had a recycling rate of 70%.

- identical distances between similar stages between the two comparison scenarios

The scope chosen is a combination of Cradle to Grave, and Cradle to Cradle for materials with recycling potential.

Sources

The LCA was calculated according to ISO 14040.

The quantitative impact data are taken from the "EF-secondary data" and "agribalyse" databases operated with the OpenLCA tool.

Useful references are below:

https://ec.europa.eu/environment/ipp/lca.htm

https://pre-sustainability.com/articles/lca-standards-and-guidelines/

https://ecochain.com/knowledge/life-cycle-assessment-lca-guide/

https://www.iso.org/fr/standard/37456.html

https://lca-net.com/publications/show/new-international-standards-life-cycle-assessment-iso-14040-iso-14044/